Mixing units

Mixing units are used to mix drilling fluid during horizontal or vertical drilling projects. Our units are built to mix bentonite, grout and other drilling fluids. This range of mixing units varies in mixing capacity of 125 up to 4000 liters per minute. We have built the first mixing unit 20 years ago and we have continued to improve these units ever since. We learn from our customers and incorporate their user experience in our design. We have optimized our range of mixing units to the highest standards available.

Check our standard units below. Contact us for more information.

M125B

125 ltr/min | 2200 x 750 x 1650 mm (LxWxH) | 260 kg

M250D

250 ltr/min | 3900 x 1000 x 2300 mm (LxWxH) | 900 kg

M405D

400 ltr/min | 2300 x 2460 x 2350 mm (LxWxH) | 1540 kg

M705D

700 ltr/min | 2300 x 2460 x 2350 mm (LxWxH) | 1740 kg

M1000E

1000 ltr/min | 6060 x 2450 x 1750 mm (LxWxH) | 5500 kg

M1010E

1000 ltr/min | 3900 x 1000 x 2300 mm (LxWxH) | 2500 kg

M1500E

1500 ltr/min | 6000 x 2450 x 2400 mm (LxWxH) | 6500 kg

M2502E

2500 ltr/min | 7200 x 2450 x 2600 mm (LxWxH) | 9500 kg

M4000E

4000 ltr/min | 12000 x 2450 x 2600 mm (LxWxH) | 9000 kg

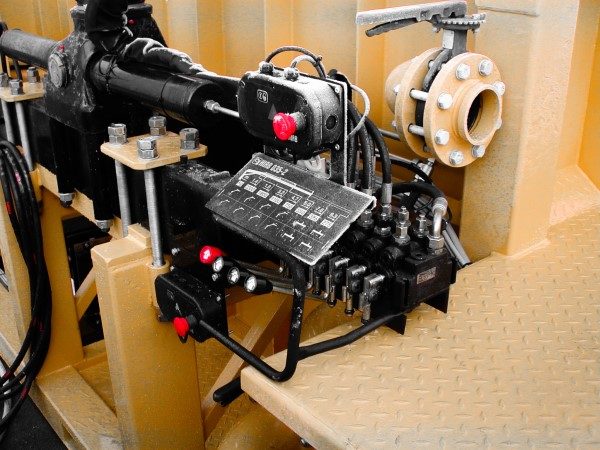

We have a wide range of mixing units. All units are easy to operate and easily accessible for maintenance. Our small footprint units are logistically highly efficient. They are built with a hopper, a venturi and nozzle system. This keeps drilling fluid in motion, which improves the shearing and its quality. We use a high quality of centrifugal pumps, which guarantees the correct combination of pressure and flow. The unit is paintable in any choice of RAL-color. They are electrically driven or run with a stage V diesel engine. The curved tank bottom is built for optimal flow and prevents settling. A dual tank is optional, just like other requirements or wishes of customers and operators. CE certification of conformity and manual are included.

We only like tough questions

We have answers! Read our frequently asked questions or contact us

We are international

We can deliver almost everywhere. Check out our dealer network