Proud to present this R1500E recycling unit!

Proud to present this R1500E recycling unit, specially designed for our British customer OCU Trenchless. A project commissioned by our well appreciated UK dealer TA drilling.

The fully electric compact recycling unit with a capacity of 1500 ltr/min is equipped with Derrick Corporation shaker and screens. We are proud of the trust that a prestigious company like Derrick Corporation put in to SiteTec for building and incorporating their world class shakers in the strong base and solid design of a SiteTec unit. With Ben Clark -global manager at Derrick Corporation- seeing the end result in our workshop and commenting that in this unit: “Best of both worlds come together;” is a big compliment.

Design recycling unit

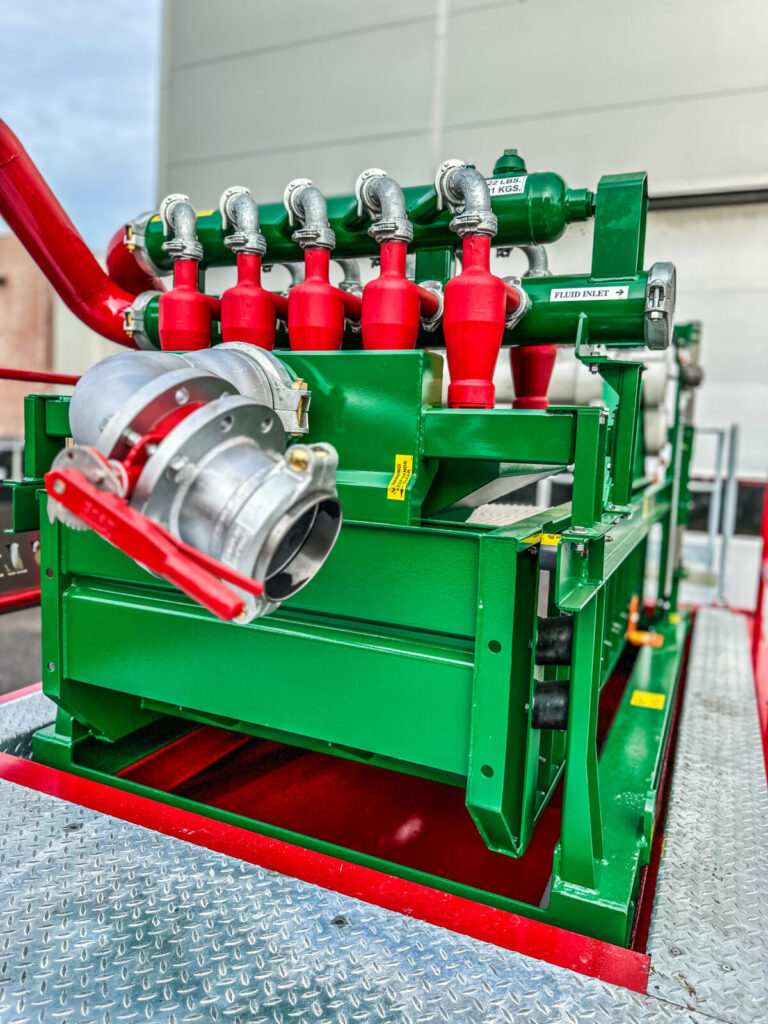

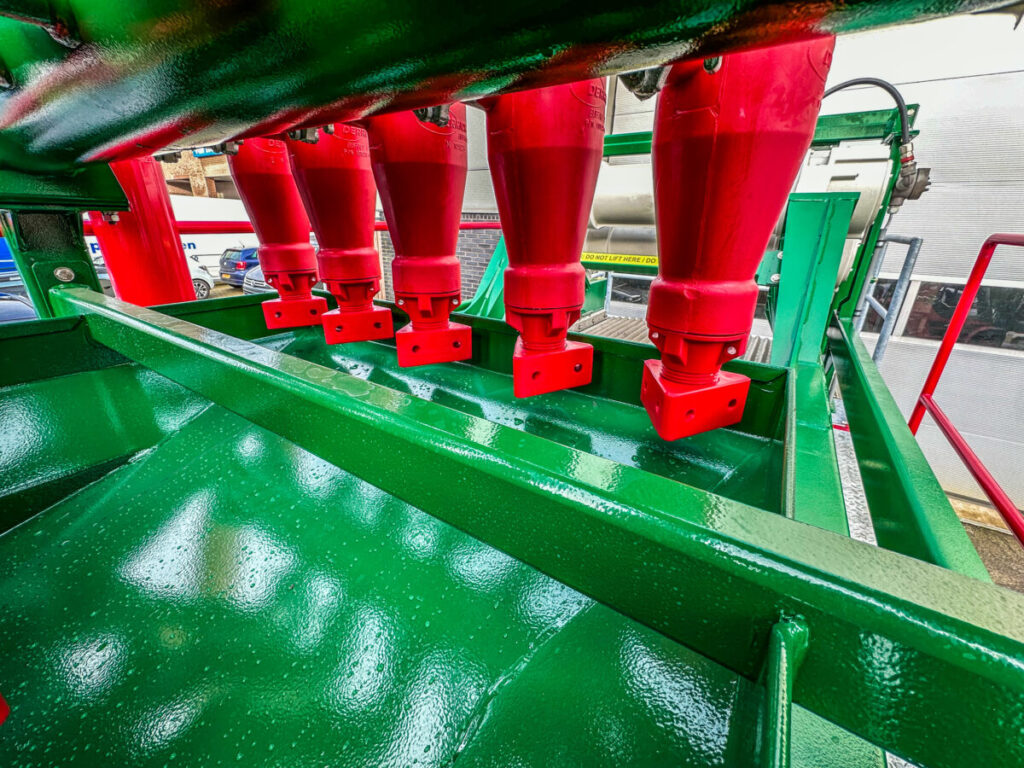

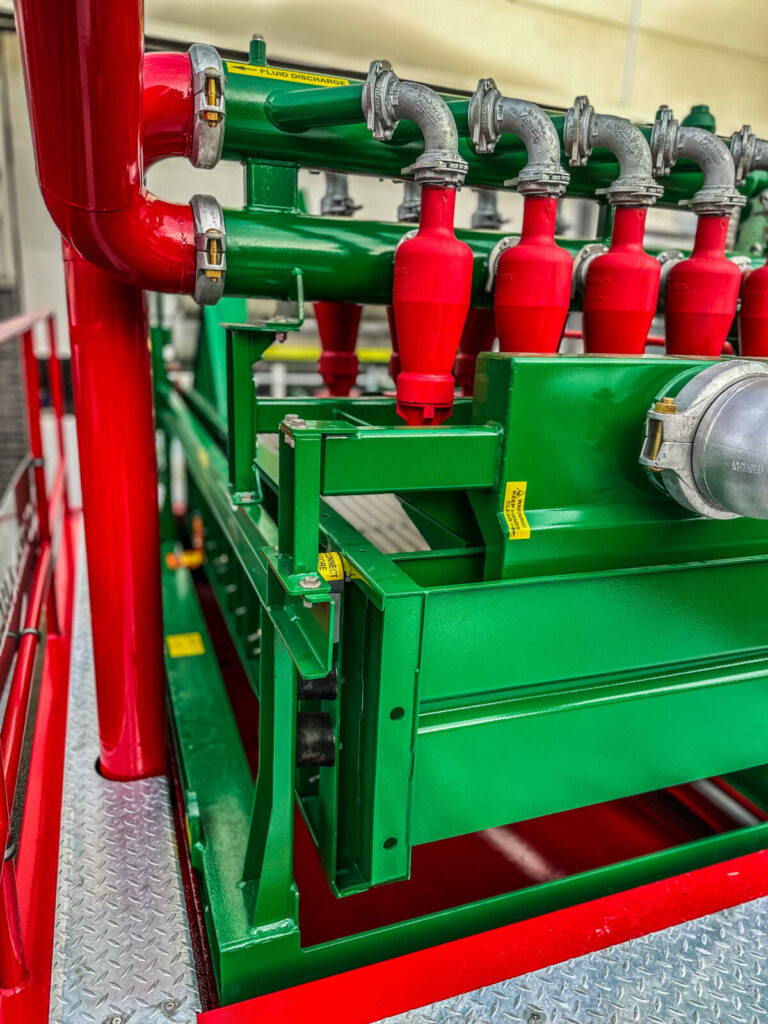

The unit is a system of hydro-cyclones, shaker and screens, collectively referred to as solids removal equipment. It separates solids out of the fluid. With a maximum of 20% incoming solids and less than 1% going out @ 60 sec viscosity 1.2 gr/cc spec. gravity. It recirculates reusable fluids, consisting of bentonite, water and other additives, back into the active fluid system: this is a closed loop. The design of this R1500E has lots of screen surface, the biggest separation volume wise is done on the shaker. The first separation of the fluid is on the polyurethan screens. After that the fluid goes to the hydro cyclones, with the final separation on the stainless pyramid screens. Since most separation is done on the shaker, the unit needs less pumping capacity for the hydro cyclones. Which makes it a unit with lots of capacity, using little power consumption.

Derrick shaker

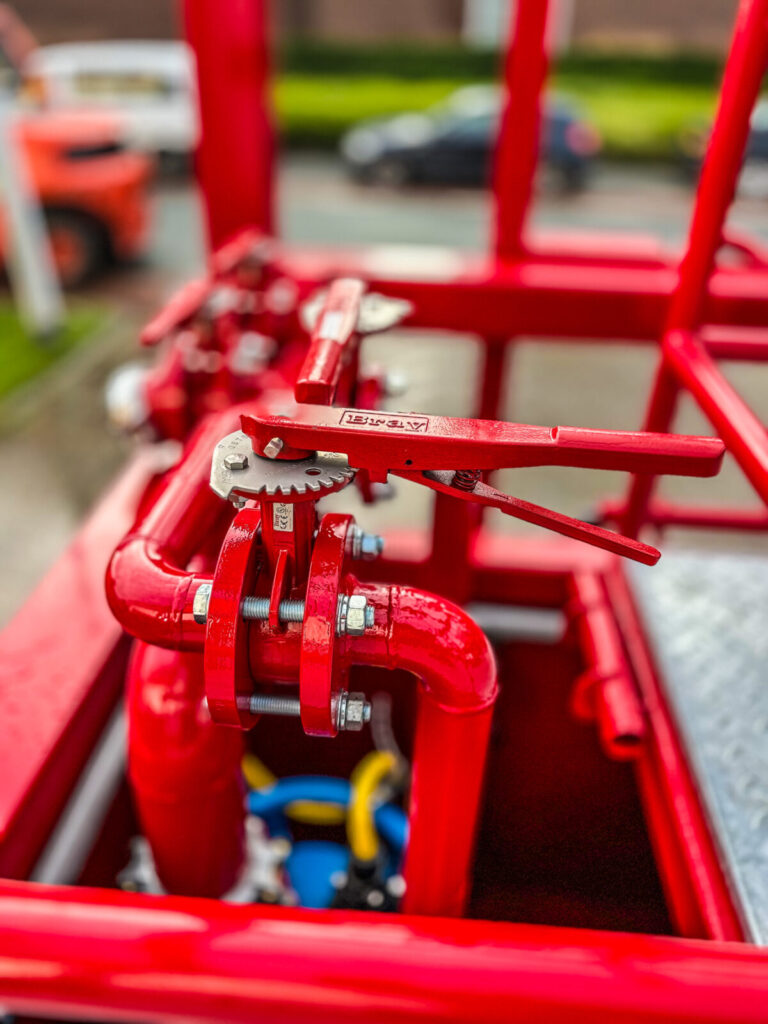

The shaker on the R1500E is a Derricks FLC shaker. A high-capacity, dual-deck, four panel per deck, vibrating screen machine. Dual vibrating motors rotate in opposite directions to produce linear motion of the screen beds. This recycling unit has a mechanical screw jack adjust while drilling. This permits the screen frame angle to be raised or lowered to optimize the flow rate across the screening beds in response to changing slurry conditions. Screen tensioning is provided by a rapid change draw bolt tensioning system, the box feeder provides an even distribution of slurry across the entire width of the screen frame. The unit is equipped with a 10-way inline desilter for removing 10- to 74 micron solids.

The sloped tank bottom and pump in the recycling unit is there for fluids to be circulated non-stop to prevent settlement. The on board transfer pump, pumps the clean fluid to the mixing unit, or recirculates in the pit. Hydro cyclones are fed by the circulation pump on the back of the unit.

Like all other SiteTec units, the R1500E is easy to operate and easily accessible for maintenance. Our small footprint units are logistically highly efficient. This unit is equipped after customers request with a hook arm system suitable for the OCU Trenchless fleet.

Complete set

This recyling unit is part of a complete set we have built for OCU Trenchless. Including a Genset on a flatbed with a 200 kVa Volvo Group diesel engine. The unit is fully sound insulated and has powerlocks for a quick, easy and safe connection. And a mixing unit M1500D, a unit with a capacity of 1500 liters per minute, powered by a stage V JCB diesel engine. The unit is equipped with a hook arm system, which makes it easy for transport and a quick setup. It also has extra space for big bags or for pallets with 25 kg bags, but still offers enough safe workingspace for the operator.

We wish OCU Trenchless many succesfull drilling meters!