A full service customer orientated project

In addition to our standard units, we construct custom build units, or like the project described below; a full service customer orientated project. We take the wishes of the customer and their operators into account. Together we look for all possibilities and the right partner for every stage of the project.

Through our client Vermeer Benelux B.V. we were asked to offer Timmermans Drilling a full service customer orientated solution. Timmermans Drilling is specialized in performing underground HDD controlled drillings. Quality, safety and environmental care are paramount at this company. Timmermans Drilling offers solutions that always strive for a minimal impact on the environment. With the help of HDD drilling techniques and the use of the right equipment, damage to the environment remains minimal. Through Vermeer Benelux they came to us to add two editions to their equipment fleet. Minimal environmental impact starts with logistics, all units must be quickly movable and deployable at different locations without too many (logistics) actions. Timmermans Drilling therefore has the complete equipment required for drilling on its own trucks. This drives easily and efficiently and the units are immediately ready for use with a minimal logistic impact. They wanted us to build two MP250H on their new Timmermans trucks. One truck will be equipped with a new Vermeer D20x22S3 drill rig and on the other truck their new Vermeer D23x30S3 drill rig.

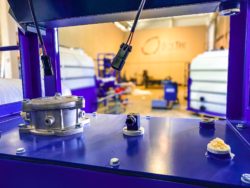

Timmermans wanted to have a mixing and pump unit with a capacity of 250 liters per minute built on the Mercedes Actros 2632. Our MP250H is a complete mixing unit with high-pressure pump built in. As standard, this unit has a 3000 liter tank, an extra 3000 liter buffer tank has been added for Timmermans. The drill rig can be driven on and off the truck safely and quickly by the specially extended and solid tail lift. The folding aluminium side flaps make the loading floor easily accessible. The hard wooden floor gives the Mercedes a nice solid finish. Our choice of partner for the construction off the bodywork was quickly made due to our excellent experience with Jos Mulder BV a well-known bodywork construction company.

Design phase

When the question of the client and the wishes of the operators are clear, our draftsman and designer can get to work. With design programs, all components are placed accurately in the construction drawing. Timmermans wants to transport all equipment from one job site in once on one truck, a great challenge to make this suitable by our designers! It is important that there is enough storage space next to the fixed location of the MP250H unit for the transportation of the drill rig, drilling tools, hoses and bentonite. When the draftsman completes the drawing, we present the design with everyone involved in the process. The construction phase starts after the final adjustments are made, and both the operators and client agree with the design.

Construction phase

We outsource components of the unit to our trusted partners, this allows parallel construction. The efforts of these experts ensure our high quality. Our job is to keep control over the process and adhere to the time schedule. Ultimately, all components come together in our workshop, where the unit is finished by our own experts.

Final phase

The unit is extensively tested in our workshop by us and our partners. Once the final checks have been completed, the unit will go to the customer. We always visit our customers at a job site to see our end product into operation. The role of the operators is very important, we learn from their user experience, together we optimize the unit.