06-10-2020

Overhauling van Vulpen’s MP500DH

Due to our way of building, our units last for many years! Maintenance, intensive use and weather conditions affect the life span of the units. When a unit is at the end of its career, the customer is faced with a choice; to purchase a new unit, to overhaul the used unit or to technically check and service the used unit?

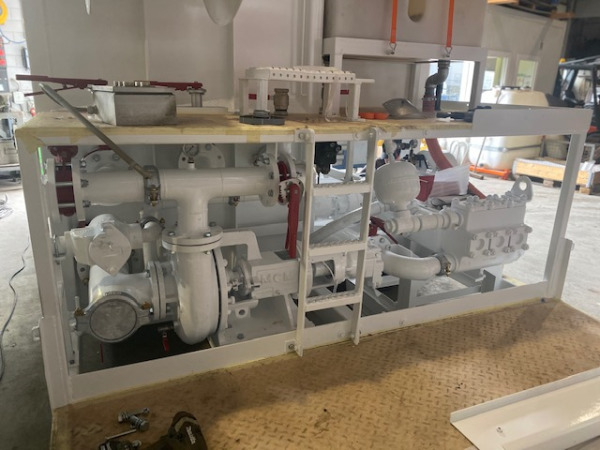

We have overhauled several units for our customer van Vulpen. The last project was the Mixing Pumping unit MP500DH from 2011. Through a complete overhauling, we have ensured that it is reliable, safe and trouble free and can last for 8000 hours! The costs are about 1/3 of the new price, which makes it a good investment for our customers.

Read below how this unit came in to our workshop and how we got it back on the road radiantly.

Before we make a quotation to the customer, we perform a thorough inspection of all components, test running under full load is part of this. The conclusion of the inspection form the basis for the quotation. After approval of our customer we got started:

- Hydraulic pumps and motors are in good condition

- Unit is completely disassembled

- Cosmetic damages repaired

- Completely new piping

- Mixing pump; all bearings and wear parts replaced

- High pressure pump; all bearings and wear parts replaced

- Components and main frame blasted and painted in customer specific colour

- New hydraulic hoses fitted

- New electrical wiring

- Electrical panels are in good condition

- Unit is reassembled

- Test run under full load

- Testing and reliable certification

- Deliver the unit to the customer who can return to jobsites in a representative and safe manner!